BRIGHT ROUNG BAR

A bright round bar is a smooth, polished steel bar, commonly used in manufacturing and machining. It is produced by cold drawing or grinding to achieve a high-quality finish with precise dimensions. Bright round bars are made from materials like carbon steel or stainless steel and are used in industries like automotive and construction for parts such as shafts, rods, and bolts. Their smooth surface and accuracy make them ideal for applications that require easy machining and durability.Their ability to withstand corrosion and fatigue, particularly in stainless steel grades, extends their usability in harsh conditions, including marine and chemical processing environments. Bright round bars are also versatile, easily fabricated, and welded, offering high flexibility for custom applications and long-term reliability in both static and dynamic systems.

| Size Range | 3mm to 120mm(1/8"-4-3/4") |

|---|---|

| Supply Condition | Cold Drawn, Centerlrss Ground,Peeled & Polished. Rough Peeled or Smooth Turned bars. Surface finish Ra 0.5umm max Straightness from 0.5mm/mtr to 1mm/mtr. 240,400,600 Grit Belt Polish |

| Heat Treatment | Soft Annealing,Soulation Annealing,Normalizing,Handerning & T empering,Oil & Water Quenching |

| Bars End Finish | Free From Burs ,Smooth saw cut , one end or both end chamfered with 45 deg |

| Specification | As per EN,DIN,JIS,ASTM,BS,ASME,GHOST,Nace MRO175/MRO 103. |

| Drade | AISI 201,202,301,302,303,304,304L,309,310,316,316L,316Ti,321,321H,347,347H,403,410,416,420,420B,420C,430,430F,431,630,15-5PH,1.4435,317L,F51,F60,2205 |

| Rough Turned tol. | DIN 1013,EN10060 |

| Tolerence | h8,h9,h11,k11,k12,k13 |

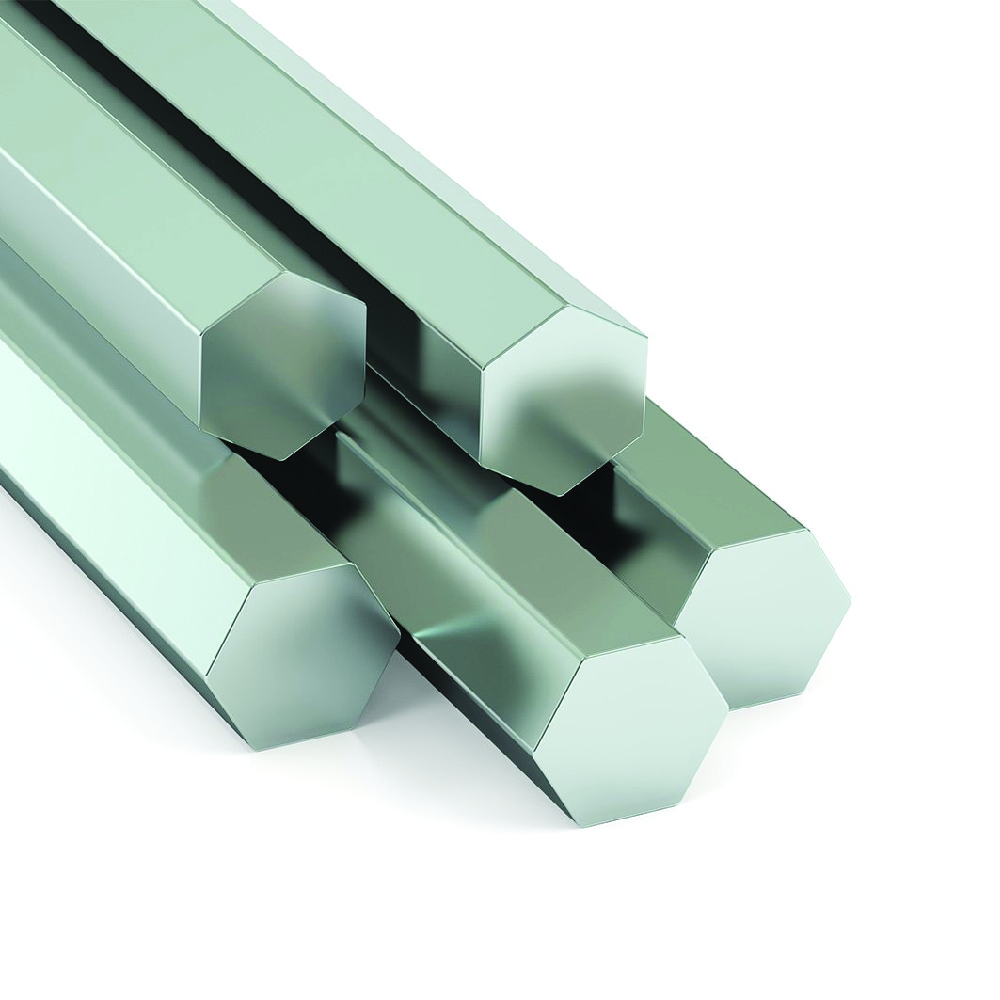

SQUARE & HEXAGONAL BRIGHT BARS

Square and hexagonal bright bars are high-precision, cold-drawn bars typically made from high-quality steel alloys. These bars are characterized by their smooth, bright surface finish, which is achieved through a process of cold drawing or polishing. Square bright bars feature a square cross-section, while hexagonal bright bars have a six-sided, hexagonal shape, making them ideal for various mechanical, structural, and manufacturing applications. They are widely used in the production of components such as shafts, fasteners, bolts, nuts, and other precision-engineered parts, where accurate dimensions and a smooth surface are essential. The bright finish of these bars not only enhances their aesthetic appeal but also improves their resistance to corrosion, making them suitable for use in industries like automotive, construction, and aerospace.

| Square Size Range | 5mm to 70mm |

|---|---|

| Hex Size Range | 5mm to 50mm |

| Length | 3 to 6 metres |

| Tolerences | h11,h12,h13 |

| Surface Finish | Cold Drawn,Shot Blast&Drawn,240 Grit Belt Polished |

| Heat Treatment | Annealed & Solution Annealed |

| Bars End Finishes | Free from Burs,Smooth Saw Cut,One End or both end chamfered with 45deg. |

STAINLESS STEEL THREADED BARS

Square and hexagonal bright bars are steel bars with smooth, polished surfaces, produced through cold drawing or grinding. Square bars have four equal sides and are used in parts like frames and supports, while hexagonal bars have six sides, commonly used for bolts and fasteners. Made from materials like carbon or stainless steel, both types offer high precision, durability, and are ideal for machining in various industries.

Application

Piston Rods, Pump,Shufts,Cylinder Shafts Precision Machined Parts, Automotive Components & Others.

| Conditions | Cold Drawn,Centreless Groung & Polished | Peeled,Centresless Ground & Polished |

|---|---|---|

| Grades | 303,304,304L,316,316L,410,416,420,430F,431,630(17-4PH)&others | |

| Diameter(Sizes) | 6mm to 25mm(1/4"to1") | 16mm to 60mm(5/8"to2-1/2") |

| Surface Finish | Up to 20 RMS Max. | Up to 20 RMS Max. |

| Diameter Tolerence | h7,h8,f7,f8,g6 | h7,h8,f7,f8,g6 |

| Straightness | Up to 0.5mm/meter(TIR 0.0015 inch per feet) | |

| Out of Roundness | Half of Diameter Tolerence | Half of Diameter Tolerence |

| Length | 3 to 7meter (12 to 22 feet) |

3 to 7meter (12 to 22 feet) |

| Heat Treatment | Soulation Annealed,Annealed,quenched & Temepered. |